Silo Cleaning Case Histories

Florida Cement Company Material Buildup

Market: Cement Industry

Material Stored: Cement

Issue: Cement storage silo that had not been cleaned since 2007 experienced significant material buildup in the hopper, impeding material flow.

A repeat customer contracted USA Silo Service to clean out a 40' diameter by 185' in height cement storage silo. The silo had not been cleaned for 15 years. A silo inspection by USA Silo Service determined that the silo contained a significant amount of material buildup.

Hot storage material was fed into the silo. This hot material met with cool air blown in through air pads, which were used without dryers, causing condensation that hydrated the cement and created huge masses of hardened material.

Most of the hardened material required specialized equipment to break it up into manageable pieces.

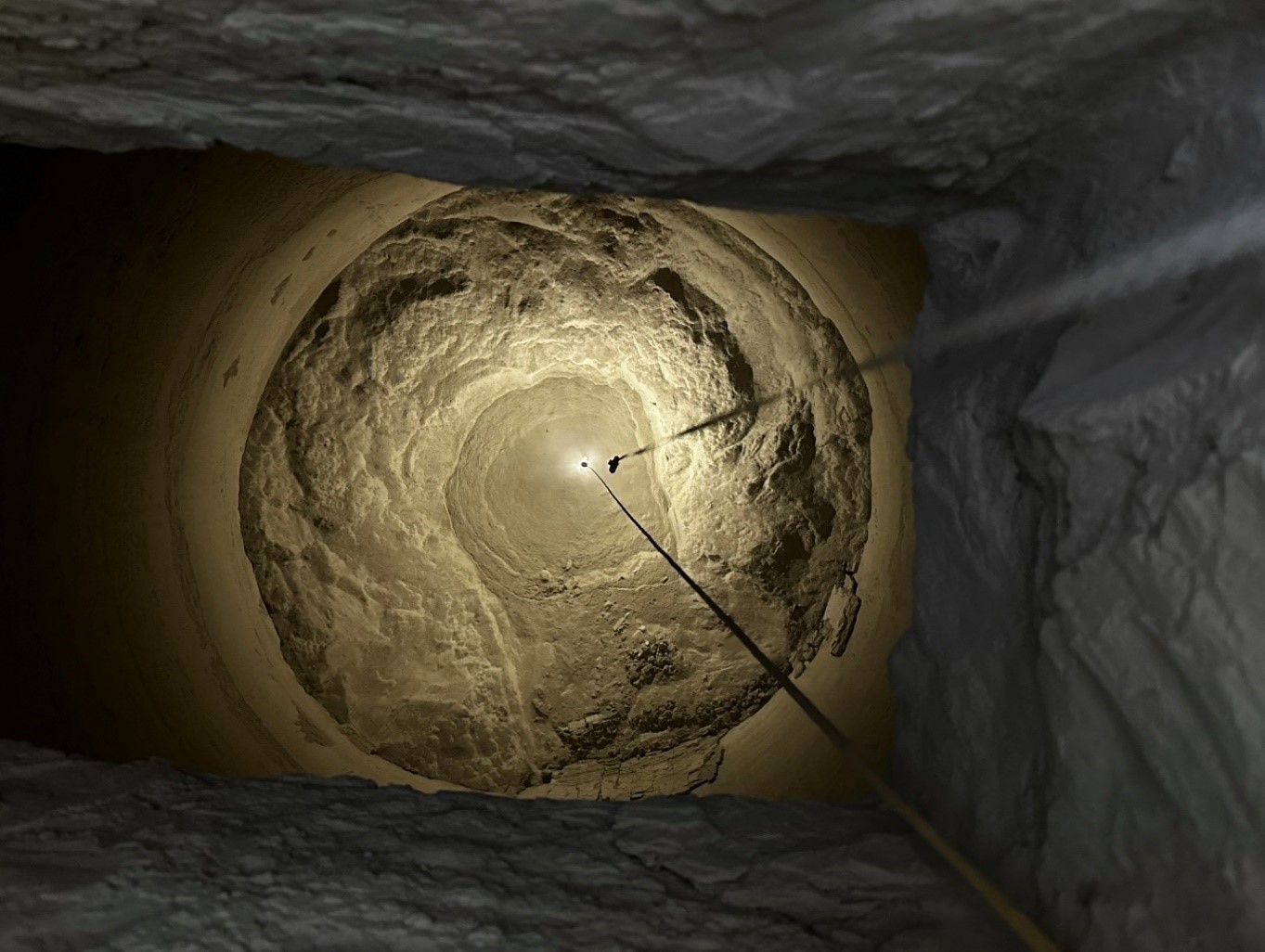

The Interior photo shows hardened material inside the silo before cleaning is performed.

Upon removal of hardened material, thorough cleaning began. USA Silos removed approximately 2500 net tons of material from this silo.

In addition to the material buildup inside the silo, the roof and underside of the roof were also covered in a substantial amount of hardened material. Significant material buildup on the roof is generally detrimental to the structural loadings of the roof beams. The material buildup noticed on the underside of the roof indicated leaking through cracks and seams on the roof.

USA Silo Service discussed the risks if left untreated with the customer, who granted the addition of roof cleaning and coating to seal off the roof from future cracks and aid in preventing buildup on the interior. These measures will help prolong the useful life of the silo and help prevent structural failure.

Photo shows rooftop that needs to be cleaned.

Picture after cleaning and coating with our proprietary material. Our exclusive rubberized coating has high bonding strength with concrete as well as extreme durability and flexibility that enables for natural expansion of rooftops.

Photo is during the cleaning process.

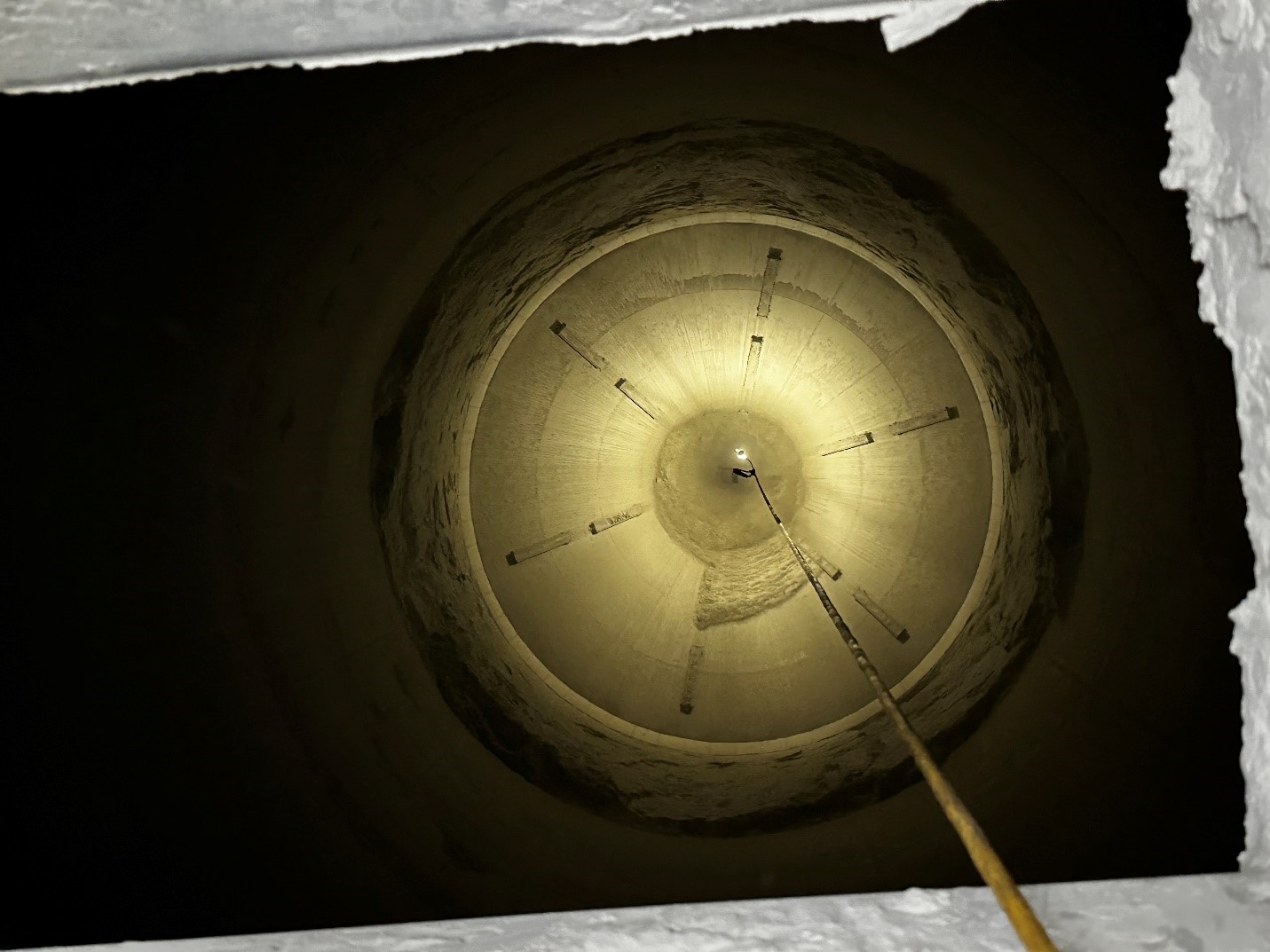

This photo is after cleaning but before the air pad repair.

Once the silo was cleaned, and the air pads were exposed, significant wear was noted. As a result, the customer requested the necessary air pad repairs and maintenance.

Air pad repairs are a complex work of art that needs to be done carefully and critically. Any abnormalities in the cloth or the airways could quickly cause a buildup of material on that side, leading to asymmetrical flow through the entire silo. This asymmetrical flow can put stress on the wall of the silo, along with excess wear and spalling of the concrete.

Photo shows air pad repair in process. The top two rows are repaired, while the bottom row still needs repair.

USA Silo Service, Inc. strives to be integral to material storage cleaning, coating, and air pad repair. Preventing material buildup is essential to ensuring the full function of your storage silo. Removing material buildup through a regular silo cleaning schedule allows you to return to original capacity immediately and for prolonged use of full capacity without leaks through your rooftop and around your rooftop framing.