2019 Blogs

When a silo has structural issues or starts clogging, so does production. Proactive maintenance is the most effective method to ensure the integrity of concrete and steel silos and is crucial to increase the life of the silo.

Bulk storage structure (e.g. silos, bins) failures don’t occur suddenly without any signal or warning. In most cases, the silo structure shows small signs of distress until the signs become too obvious and have caused the structure to fail and potentially collapse. Much of this damage is easily preventable through routine silo maintenance and inspection. Many structural issues can be easily and economically addressed if caught early.

What to Examine Yourself

Silo Roofs

Roofs are an essential part of the silo structure. During in-house inspections, you should look for signs of cracking or peeling in the roof-top coating. Leaking roofs can lead to contamination of stored materials that impacts product quality.

Water penetration also leads to corrosion of metal silo components like roof beams – an issue that can lead to total roof failure if not addressed. Roof beams are a frequent area of corrosion, often due to roof leaks. Spalling of concrete on roof beam pockets can further expose beams and easily lead to a roof failure or collapse. You should also look for signs of ponding water on the silo roof. Regular ponding that sits on the silo roof lowers the lifespan of coating membranes and can lead to deterioration and leaks. More seriously, ponding water is usually caused by issues with the roof beam that supports the roof and can indicate potentially severe structural problems. Left unaddressed, these problems become costlier to correct and increase liabilities.

Exterior Surfaces

Though concrete is a superior material for the construction of storage silos, normal loading and unloading operations can lead to structural issues over time. Cracks in silo walls, linings, roofs and foundations are an indication of stress.

Concrete walls that show horizontal, vertical or diagonal cracking may be an indication of delamination, or separation of the concrete into layers. A serious issue, delamination of silo walls can lead to wall failure or collapse and should be addressed by a professional silo repair company immediately. Corrosion or buckling of metal silo components, exposed rebar or other deterioration like spalling should also be noted during a visual inspection.

In-house inspections should include verification that preventive maintenance measures are being followed. Silo maintenance should include regular checks of airflow systems, a routine professional cleaning and regular, complete silo emptying. Of these measures, one of the most important is the regular emptying of silos.

Silos that are regularly emptied and refilled are less likely to experience buildup issues seen in those kept topped off. Regularly emptied silos need professional cleaning less frequently in comparison. They are also less likely to experience problems like compacting and hydrating. Hydration occurs when moisture mixes with stored materials and causes them to solidify within the silo. When this happens, materials can expand and cause added wall pressure which increases the likelihood of structural failure. Lime and cement are highly susceptible to compacting and hydrating respectively.

Silo Maintenance Checklist

Prepare a preventive maintenance checklist to facilitate data recording and referencing that clearly establishes which components are to be evaluated and which inspection criteria to use.

- If your silo is constructed of reinforced concrete, check for any signs of corrosion, exposed rebar, unusual cracking, concrete spalling or wall stains indicating leakage.

- If you have a metal silo, look for bolted joints near the hopper’s top, waviness along the sheet edges, bolt hole elongation, cracks between bolt holes, outward bulging of the cone shell near the top and damage at vertical seams.

- Determine minimum wall thicknesses required for structural integrity and compare these to your silo’s actual wall thickness.

- Look for and repair or replace damaged or loose liners.

- Remove material buildup that could trap moisture on the outdoor silos’ exterior.

- Check for warning signs, air blowing in or out of vents, wear patterns, vibration or spillage.

- Inspect and maintain mechanical equipment including gates, feeders and dischargers. (When repairing or replacing any mechanical component, remember that seemingly innocuous changes can have significant effects)

If you spot anything wrong during your routine maintenance checks, stop discharging and filling the silo so you can assess the structure’s integrity, and summon expert help.

In addition, annually inspect all alloy, aluminum, stainless steel, and plated components, checking for corrosion, intergranular cracking, pitting, and deterioration. Verify that all bolted connections are properly torqued, retighten loose connections, and re-examine them within 3 months. Annually inspect the interior and exterior finish for damage, wear, or corrosion, and touch them up or repair them as needed.

Every 6 months, inspect the guardrails for looseness or damage, the wear liners for erosion, the ladders for looseness, and the manholes for proper alignment and fit. Check gaskets for unusual wear, and lubricate hinges as needed. Once every 3 months, inspect all relief valves and vents to make sure they’re clear, free, and operational. It’s also important to verify that safety signs are applied to manholes and all attached equipment, and that all personnel have read and understood them. You should always perform a post-disaster examination of the silo and all components and make sure that problems are immediately corrected.

When it comes to keeping your silo clean and running efficiently day in and day out, it's vital that you are proactive with preventive silo maintenance. Marietta Silos and USA Silos are the leading industry experts when it comes to silo inspection, cleaning, maintenance, and repair. Contact us today to schedule a silo inspection.

Be sure to check out our full library of silo maintenance videos on ![]()

Reference:

https://www.powderbulk.com/wp-content/uploads/2014/05/PBE_20041101_60.pdf

When it comes to keeping your silo clean and running efficiently day in and day out, it’s vital that you are proactive with preventive silo maintenance. One of the most important is checking your silo roof and walls to make sure they are leakproof.

Many concrete silos have either a membrane cover, a concrete slab or other material covering the silo roof. Over time, roof covers develop holes, allowing water intrusion under the roof cover material. Once the water gets underneath, it is trapped and eventually travels along the concrete roof to a crack. Once the trapped water finds an opening, water can make its way into the silo and compromise stored materials. Natural freeze and thaw cycles allow water to expand and contract inside fine exterior cracks and jeopardize a silo’s structural stability.

Our Roof-Top and Exterior Wall Coating Method

It’s essential that your silo is completely watertight. Even pinhole leaks in silo roofs and walls can damage stored materials and can result in blockages and material flow issues. When selecting a roof covering for a concrete silo, it is critical to select a coating that adheres directly to concrete, rather than a roof cover that merely conceals the concrete roof and can hide future issues.

USA Silo Service has developed a unique silo roof and silo wall sealing method, a rubber product that applies to a concrete or steel silo roof to cover cracks, holes and equipment attachment areas.

This sealing method can be used for roof surfaces or for steel bolted silo joints to offer excellent protection against oxidation, humidity and corrosive environments. Our rubberized coating also resists alkali, salts, abrasions and fumes.

Additional benefits of roof-top silo coatings:

- Not a floating membrane

- Offers excellent adhesion to aluminum, galvanized steel, painted surfaces, modified bitumen, steel joints and many other surfaces

- Excellent in sealing cracks, laps, fasteners and roof surface penetrations

- Available in all 50 states and in a variety of colors

Our rubber coating reduces costly reapplications of surface protectants and can be applied to many surfaces including: metal buildings and roofs, built up roof (BUR) membranes, grain silos and bins, silo exterior walls, single ply roofs, urethane foam roofs and steel bolted joints.

Our roof-top silo coating method is a proven industrial roof coating system that keeps elements out and stored materials dry. Request a quote from us today.

See Case History – Does Your Concrete Silo Roof Leak?

Be sure to check out our full library of silo maintenance videos on

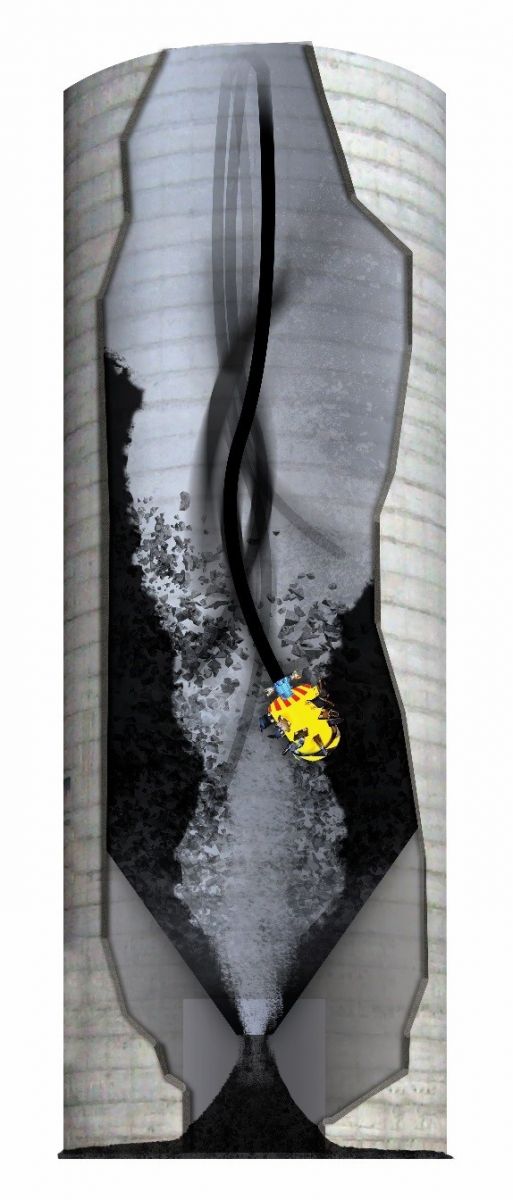

- Remove material buildup

- Restore flow rates

- Recover silo capacity

- Prevent cross contamination

- Reclaim lost material

Our silo cleaning methods will save you the most time and money.